glacier_freeze

Member

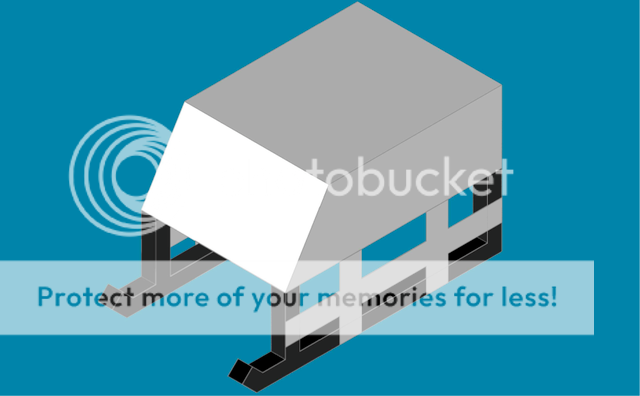

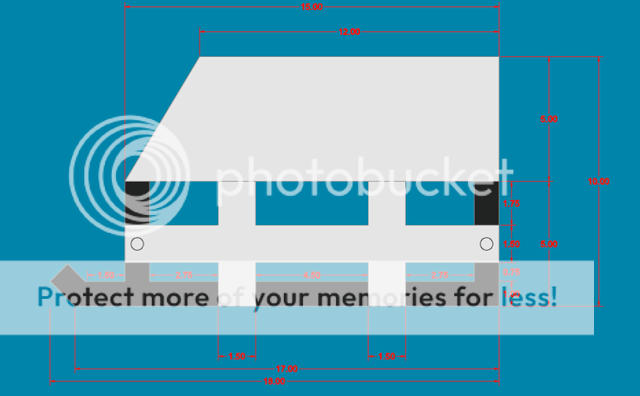

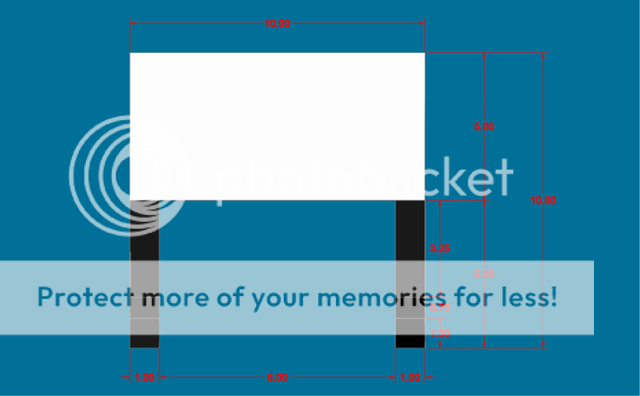

StartFragmentIf you arewilling to act as a mentor for a few simple questions regarding theconstruction of a Remotely Operated Vehicle for my HS Systems Engineering IIclass, please send a PM or reply via a PM (for any simple suggestions orquestions regarding the project, you can reply via email. but i need the email-ishformat for my teachers. Background:constructinga Remotely Operated Vehicle (ROV)assigned toconstruct the vehicle structurethe vehiclestructure is mainly being constructed from aluminum and HDPE Questions:What weldingtechnique is required for 5052-H32 aluminum sheet (36 inches x 36 inches, 0.05inches thickness? TIG welding or MIG welding How can Iwater/pressure seal the edges of the aluminum? epoxy How can Icut the aluminum sheet effectively? band saw How can Ibend the aluminum sheet to form edges? How can Iattach the aluminum body to the High Density Polyethlyene (HDPE) skids?fasteners What type offasteners (like screws) can be used to attach aluminum to HDPE? Note: the HDPEis ideally 1 inch in thickness, but I can order 1.25 inch thick HDPE? I haveattached a picture of the proposed ROV design.

morereliable background. (this is the ROV competition website that the schoolcompetes in) http://www.materover.org/main/(its a remotely operated underwater vehicle.) http://www.seabotix.com/products/vlbv950.htm i am sort ofbasing my design off of this company's idea of using skids, because we need touse hydrophones and thermometers to take measurements basicallythe class consists of one project - the capstone design project, where wecombine our knowledge and experience from 'technology and problem solving'class from 9th grade, 'AutoCAD' from 10th grade, and 'Sys. Engineering I' from11th grade. however, we are required to use a mentor, so i ask this communityfor more help beyond my mentor, because i know there are some engineeringmajors in the group. any suggestions help. really just trying to gather as muchadvice, because i need to fill out mentor contacts for tuesday. @ 'TheReverend Floater' thanks. @ 'DoWork'much appreciated advice. i plan on bending it by creating a net initially. so iwill go ahead with bending the aluminum with a brake. sorry but i am not handyat all. my dad does not touch anything, so I am slowly picking up on stuff in school. http://www.mathsisfun.com/cube.html unfortunately,i am not at school anymore (where the drawings are). 3rd point - air tight(ballast for buoyancy); the ROV will be at a max of 4 meters underwater(chlorinated indoor pool). and no i don't have to open the aluminum body uponce its welded. thanks for the knowledge about the welds holding up and theadvice on the rivets. it should not matter, but i truthfully don't know. i wasthinking screws but i didn't know what screws would work best with hdpe (i'mafraid of splintering). the HDPE will be made from 1 inch thick HDPE. if i gothe screw route, any suggestions on screws that can drill into 1 inch thickHDPE. i would love to make it all aluminum but i need the skids to provide astable platform. @'pointemstraight' thanks. i will test the aluminum with both approaches atfirst. and are you referring to snips or actually metal shears. i know we havesnips because i had to help a classmate cut slotted aluminum with snips, but iwill have to ask the teacher about metal shears. and i'll look into the brake. lastly, myblog for additional information that includes lead up background, the problem,some more drawings (but basically the same view). maybe the description of thealternate solutions could help. http://se2aengrov.blogspot.com/ also the competition website might help.EndFragment

morereliable background. (this is the ROV competition website that the schoolcompetes in) http://www.materover.org/main/(its a remotely operated underwater vehicle.) http://www.seabotix.com/products/vlbv950.htm i am sort ofbasing my design off of this company's idea of using skids, because we need touse hydrophones and thermometers to take measurements basicallythe class consists of one project - the capstone design project, where wecombine our knowledge and experience from 'technology and problem solving'class from 9th grade, 'AutoCAD' from 10th grade, and 'Sys. Engineering I' from11th grade. however, we are required to use a mentor, so i ask this communityfor more help beyond my mentor, because i know there are some engineeringmajors in the group. any suggestions help. really just trying to gather as muchadvice, because i need to fill out mentor contacts for tuesday. @ 'TheReverend Floater' thanks. @ 'DoWork'much appreciated advice. i plan on bending it by creating a net initially. so iwill go ahead with bending the aluminum with a brake. sorry but i am not handyat all. my dad does not touch anything, so I am slowly picking up on stuff in school. http://www.mathsisfun.com/cube.html unfortunately,i am not at school anymore (where the drawings are). 3rd point - air tight(ballast for buoyancy); the ROV will be at a max of 4 meters underwater(chlorinated indoor pool). and no i don't have to open the aluminum body uponce its welded. thanks for the knowledge about the welds holding up and theadvice on the rivets. it should not matter, but i truthfully don't know. i wasthinking screws but i didn't know what screws would work best with hdpe (i'mafraid of splintering). the HDPE will be made from 1 inch thick HDPE. if i gothe screw route, any suggestions on screws that can drill into 1 inch thickHDPE. i would love to make it all aluminum but i need the skids to provide astable platform. @'pointemstraight' thanks. i will test the aluminum with both approaches atfirst. and are you referring to snips or actually metal shears. i know we havesnips because i had to help a classmate cut slotted aluminum with snips, but iwill have to ask the teacher about metal shears. and i'll look into the brake. lastly, myblog for additional information that includes lead up background, the problem,some more drawings (but basically the same view). maybe the description of thealternate solutions could help. http://se2aengrov.blogspot.com/ also the competition website might help.EndFragment