So…finally ready to make a big post about what has been a big part of my life these last few years.

Project has been called ON3P skis. I can almost hear the moans and associated eye rolls of a lot of people who are sick of hearing about more and more ski companies coming out over these past few years. I have been thinking the same thing and it has definitely been compounded by my desire to be building my own skis. But bear with me…..

The idea started right after getting a pair of custom skis that basically turned out to be a big disappointment to me. They were not bad skis, but just not what I expected or asked for. This was in the spring of 2006 when I was finishing up my sophomore year of college at the UPS in Tacoma, WA.

Quick note. It is said O N 3 P. Just say it out. I have some friends who say it One 3 P. It stands for thirteenth and proctor which was the house I lived at when this idea started. But again, really simple. O N 3 P Skis.

As I thought about it more and more, I got it in my head that I should just build my own skis. Low and behold, I had no idea what I was getting myself into. Cost wise, this project has cost me over 6 times what I originally expected. Granted, we have made 52 pairs of skis so far, but it took a ton of work to get where I am right now.

One of the biggest difficulties for me was that I was in college the whole time this was going on. Not only did I not have a lot of available funding (there were months were all I could really do one month was buy one tool, then another, and so on until I had everything I need), I did not have a lot of available time. I just graduated last may, and was studying biology with a premedical focus, so I was working pretty hard in school already. This was especially compounded by a 10 month thesis research project running crabs on treadmills (I shit you not….I ran crabs on treadmills….yup) that basically kept me in the library or lab 24/7 the last semester of my senior year.

At this point, I have graduated and really trying to see if I can get funding to make these skis available next year. With today’s economy, this is being pretty difficult. But I am pretty determined to get it done.

Anyway, basically I will give a photo guide of everything that I had to do to get this done. This involved designing and constructing my own ski press, learning how to use a ton of tools I had never used before, like routers, band, jig, and table saws, dremel, drills, etc. etc, and then learning how to design molds and skis shapes, and FINALLY getting to make some skis.

I didn’t want to half ass it, and while my skis are definitely not perfect, I think they came out pretty damn good and can only get better from here. So far I have made 52 pairs of prototypes and hope to get more out this year, but that all depends on funding.

Anyway, now to all the photos.

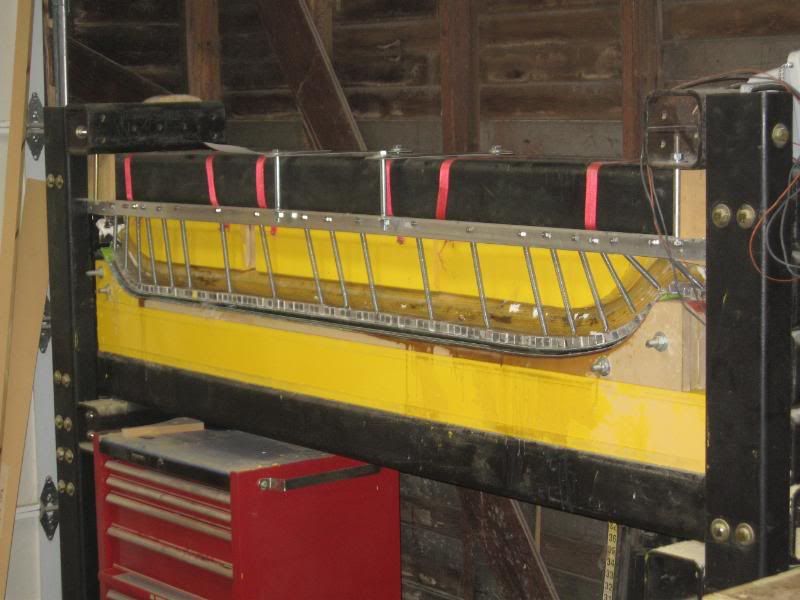

Painting the ski for the ski press. Thanks to Gabe (Jumper Bones) for the help getting all the steel to my house.

From here, I had to drill the steel. This was…..an interesting process for me. Steel was ½” steel, and all the holes I drilled were ½” wide, so when all was said and done, I had drilled some ridiculous amount like 15 feet of steel.

The hard thing was to make sure everything fit together well. It took me some time to figure out how to get everything drilled correctly, along with the difficult task of moving and drill beams that were almost 300 lbs each, sometimes right next to each other. But when all was said and done (after a lot of drilling), it was all worth it.

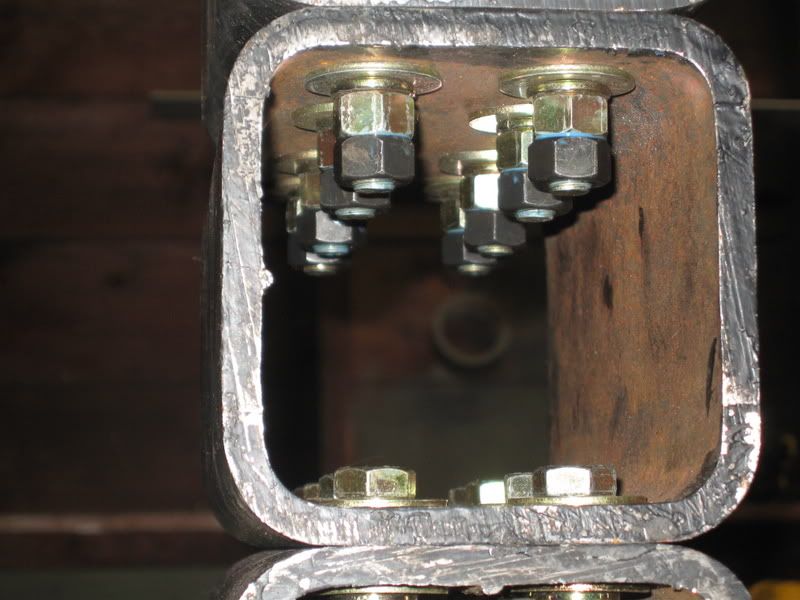

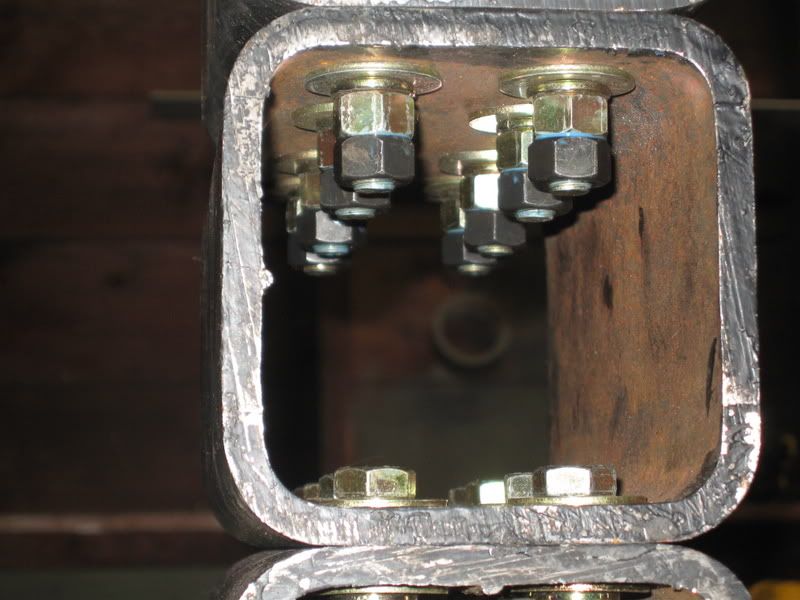

I used grade 8 bolts, lock nuts, and at least 2 nuts (sometimes 3) one each of the 148+ bolts that hold the press together. I will be building a new press soon that will be welded, so the time to build it will pale in comparison….anyway, press construction.

Legs coming together

From here, we finally had the moment of truth. Will everything fir together? The press was basically 3 parts; a main press cavity and two leg sections. When it was all said and done, I was so stoked that it turned out.

Best toll EVER for getting the legs on

Press finally came together, and looked great.

So then I moved from the house this idea started out to a new house. Located was great because it was with a few blocks of 10 bars….BUT shop wise, conditions were tight. The shop was 13’ x 17’ and had only 2 110V lines. Ek. But I made due, and had to build it up a lot.

Lots of work to go

So now I had to go and make the best of the space I had. So I build up the shop from the ground up.

When the shop was finally done, I was pretty sure even with the less than 300 square feet I had, I could get everything in there and get this all done.

Go tools

After I made the base mold, I had my rocker sections cnc’ed. I wanted to have the ability to easily swap between different rocker sections, so I designed 3 different rockers, between 15 and 35cm that were easily interchangeable.

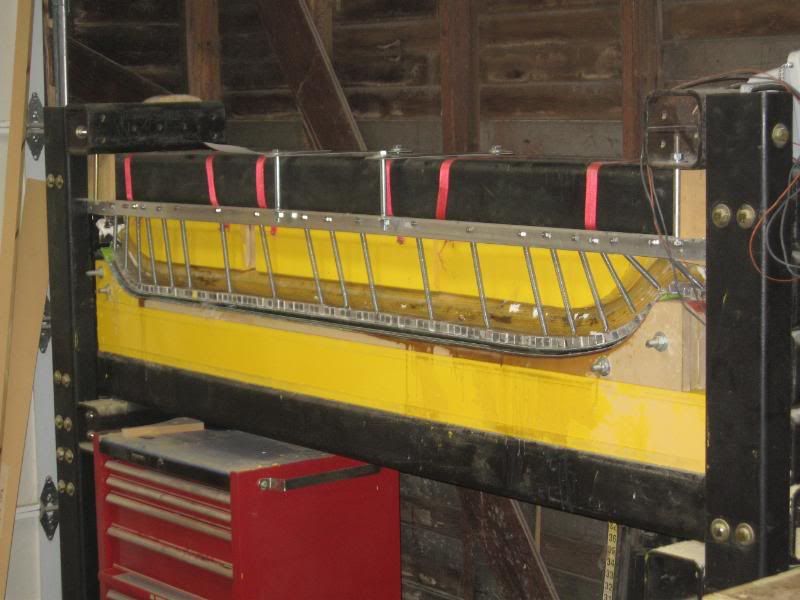

I then got the cat track cut, top and bottom molds finished, and put the press together.

I use a planer crib to make my cores. I made an adjustable crib that was not perfect, but it works to do almost 110 cores with 9 different core profiles…

Anyway, first ski out of the press was meh. I don’t really know how it happened, but all of a sudden I knew was that suddenly I laying up a ski scared shitless wondering what I was doing. Very very similar to your first time having sex if I remember to my teenage years correctly.

I used WAY too much epoxy.

Cat approve

Next to the FFFs

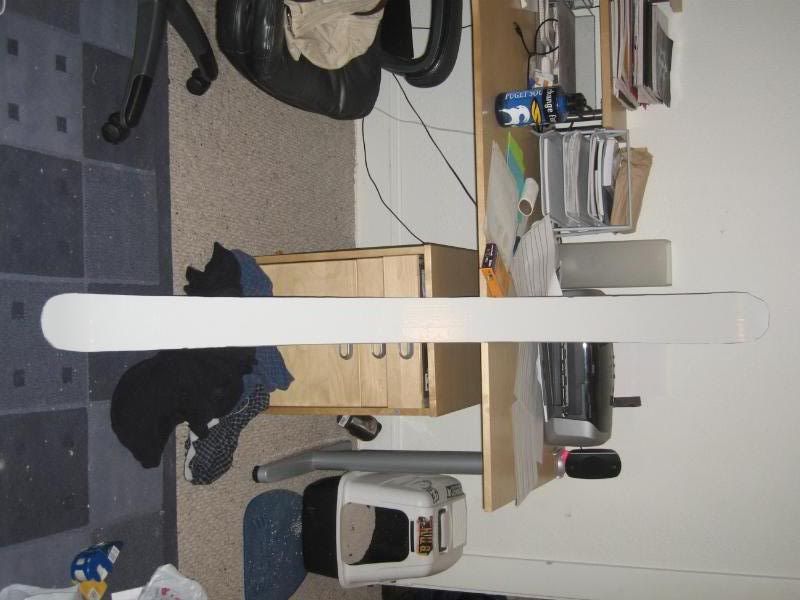

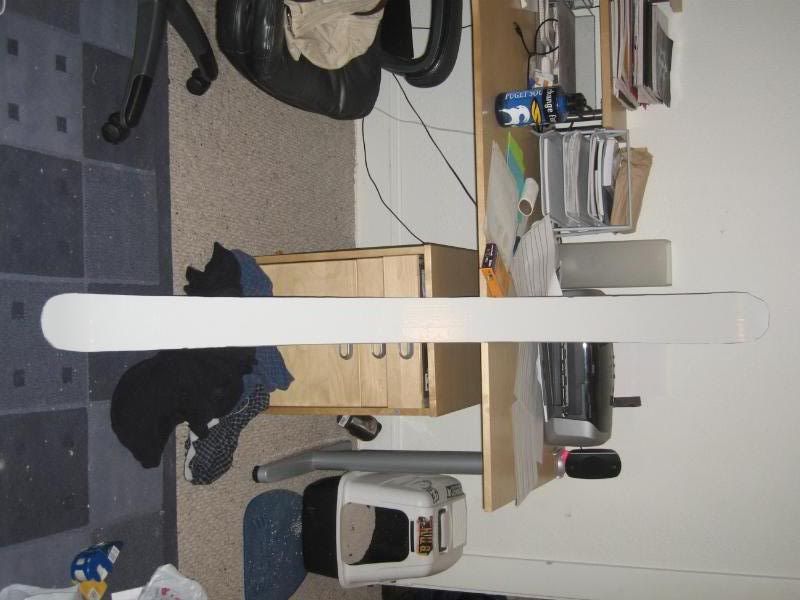

Next ski came out better.

After getting 2 skis under my belt, I pressed the first pair I would get to ski on.

Skied them up a crystal. Several other people got to use them and everyone seemed to like them.

Git ir done

Buddy david took them out too

Anyway, kept on working and got a few more pairs out. Here is the girlfriend showing off Wren’s wrenegades.

Then things picked up a lot. I stated off expecting to make 7 pairs of skis at first. Well at the end we had produced 52 pairs.

VDS

Cutting jig

Tipspacers

Base material

Fiberglass broken up by size

Some cores

Rest of cores

From here on I could show a ridiculous amount of photos, but I will just throw a handful up.

At the end I had a lot of help from friends just helping me get the skis done. First and foremost, Sam Caylor. His is the man and he cut and finished a ton of skis.

Also David, Billy, Rowen, Will, and Josh all showed up to help get the skis done.

Will with his skis

One of the things that was the hardest part for me was hand cutting the edge notch of the ski. Sometimes I did a good job, other times not as well.

Before

After

Zoe’s custom pair vs. a pair of caylors

Where I lived there was 10+ ally cats. They are great company

Marshal’s Great Scotts getting layed up

Wood veneer

Anyway, that is obviously a lot of photos.

When all was said and done I had made 52 different skis.

Anyway, here is the info about the skis.

191cm Great Scott

145/125/130 corresponding to running length

Running Length = 122cm

Tip rocker = 25cm x 2 or 2.5cm

Tail rocker = 15cm x 1.5cm

Turn Radius = 29.8m

Tapered Tip and Tail

Mount = -8cm

191 Caylor

147/121/144

Running Length = 92cm (go skiboards!)

Tip Rocker = 35cm x 2.5cm

Tail Rocker = 35cm x 2.5cm

Turn Radius = 26.8m

Mount = -3cm

191cm Wrenegade

141/113/128

Running Length = 162cm

Tip Rocker = 15cm x 1.5cm (rec)

Tail Rocker = N/A

Turn Radius = 30.5m

Mount = -9cm

186 Billy Goat

140/115/120 corresponding to running length

Running Length = 117cm

Tip Rocker = 25cm x 2cm

Tail Rocker = 15cm x 1.5cm

Turn Radius = 22.8m

Mount = -7.5cm

186cm Jeronimo

145/115/142

Running Length = 157cm

Tip Rocker = 25cm x 2cm

Tail Rocker = 15cm x 1.5cm

Turn Radius = 21.6m

Mount = -3cm

186cm JBS

132/104/120

Running Length = 157cm

Tip Rocker = 15cm x 1.5cm

Tail Rocker = NA

Turn Radius = 28m

Mount = -7.5cm

179 Custom (unnamed) – Right now full custom

135/110/115 corresponding to running length (15cm tip taper, normal tail)

Running Length = 137cm

Tip Rocker = 15cm x 1.5cm (rec)

Tail Rocker = NA

Turn Radius = 30.5m

Mount = -6cm

179 Blue Steele

111/85/111

Running Length = 150cm

Tip Rocker = NA or 15cm x 1.5cm

Tail Rocker = NA or 15cm x 1.5cm

Turn Radius = 21.6m

Mount = Center

Here is a quiver pic of my skis and the breakdown.

191cm ON3P Great Scott w/ s916. -8cm from center. 145/125/130

191cm ON3P Caylor w/ s916. -3cm from center. 147/121/144

191cm ON3P Wrenegade w/ s916. -9cm from center. 141/113/128

191cm ON3P Wrenegade w/ P12 Demo. -9cm from center. 141/113/128

186cm ON3P Jeronimo w/ s916. -3cm from center. 145/115/142

186cm ON3P Jeronimo w/ P12 Demo. -3cm from center. 145/115/142

186cm ON3P JBS w/ 997 Demo. -7.5cm from center. 132/104/120

179cm ON3P Blue Steele w/ FKS120. Dead Center. 111/85/111

163cm ON3P Customs for the girlfriend. 120/90/110

Rocker shot

As you go along skis: tip rocker: tail rocker

Great Scott: 25cm x 2cm: 15cm x 1.5cm

Caylor: 35cm x 2.5cm: 35cm x 2.5cm

Wrenegade: 15cm x 1.5cm: flat

Wrenegade: 15cm x 1.5cm: flat

Jeronimo: 25cm x 2cm: 25cm x 2cm

Jeronimo: 25cm x 2cm: 25cm x 2cm

JBS: 25cm x 2cm: 15cm x 1.5cm

Blue Steele: flat: flat

Girlfriends skis: 15cm x 1.5cm: flat

and gotta have one of the cats somewhere in the photos

And a few pics of the skis getting tested in Montana over the summer. Skier is David Steele.

Skis are bamboo core, currently PBT topsheet, 4001 race base, 2.2mm/1.3mm edges, VDS, 22oz glass, carbon fiber, fiberglass binding mat.

Production skis if they ever happen would change over to screen printed topsheets as well as bases, UHMW sidewalls (currently bamboo), but otherwise should be pretty similar.

So yeah, I figured I would just get a post out there. If any of the other kids who got skis want to post something up, by all means do. This project has been a huge part of my life and I would love to make it into a full blown ski company.

Ideally I would like to do something where you were given at least a choice in topsheet and flex, and possible rocker, but we shall see.

Right now trying to get funding to get a real shop (hopefully moving from about 300 square feet to 2000-3000 square feet), materials at an affordable cost (right now my cost was huge), and better tools.

Currently in Portland, so if you are skiing around Hood or Crystal/Baker, I should have demos I would love people to try. I have a 301mm boot, too, so if anyone has a boot sole close to mine you are welcomed to try my skis as well.

Questions, comments, etc are definitely welcomes. Even let me know what skis you want made. I definitely have some ideas, but the more input the better.

We should have a website up soon as soon as I can afford it. www.on3pskis.com will be the address. So yeah, that is it mostly. I hope those who got the skis like them And to those hoping to get the skis, hopefully I can make some stuff that you think kicks ass.

Project has been called ON3P skis. I can almost hear the moans and associated eye rolls of a lot of people who are sick of hearing about more and more ski companies coming out over these past few years. I have been thinking the same thing and it has definitely been compounded by my desire to be building my own skis. But bear with me…..

The idea started right after getting a pair of custom skis that basically turned out to be a big disappointment to me. They were not bad skis, but just not what I expected or asked for. This was in the spring of 2006 when I was finishing up my sophomore year of college at the UPS in Tacoma, WA.

Quick note. It is said O N 3 P. Just say it out. I have some friends who say it One 3 P. It stands for thirteenth and proctor which was the house I lived at when this idea started. But again, really simple. O N 3 P Skis.

As I thought about it more and more, I got it in my head that I should just build my own skis. Low and behold, I had no idea what I was getting myself into. Cost wise, this project has cost me over 6 times what I originally expected. Granted, we have made 52 pairs of skis so far, but it took a ton of work to get where I am right now.

One of the biggest difficulties for me was that I was in college the whole time this was going on. Not only did I not have a lot of available funding (there were months were all I could really do one month was buy one tool, then another, and so on until I had everything I need), I did not have a lot of available time. I just graduated last may, and was studying biology with a premedical focus, so I was working pretty hard in school already. This was especially compounded by a 10 month thesis research project running crabs on treadmills (I shit you not….I ran crabs on treadmills….yup) that basically kept me in the library or lab 24/7 the last semester of my senior year.

At this point, I have graduated and really trying to see if I can get funding to make these skis available next year. With today’s economy, this is being pretty difficult. But I am pretty determined to get it done.

Anyway, basically I will give a photo guide of everything that I had to do to get this done. This involved designing and constructing my own ski press, learning how to use a ton of tools I had never used before, like routers, band, jig, and table saws, dremel, drills, etc. etc, and then learning how to design molds and skis shapes, and FINALLY getting to make some skis.

I didn’t want to half ass it, and while my skis are definitely not perfect, I think they came out pretty damn good and can only get better from here. So far I have made 52 pairs of prototypes and hope to get more out this year, but that all depends on funding.

Anyway, now to all the photos.

Painting the ski for the ski press. Thanks to Gabe (Jumper Bones) for the help getting all the steel to my house.

From here, I had to drill the steel. This was…..an interesting process for me. Steel was ½” steel, and all the holes I drilled were ½” wide, so when all was said and done, I had drilled some ridiculous amount like 15 feet of steel.

The hard thing was to make sure everything fit together well. It took me some time to figure out how to get everything drilled correctly, along with the difficult task of moving and drill beams that were almost 300 lbs each, sometimes right next to each other. But when all was said and done (after a lot of drilling), it was all worth it.

I used grade 8 bolts, lock nuts, and at least 2 nuts (sometimes 3) one each of the 148+ bolts that hold the press together. I will be building a new press soon that will be welded, so the time to build it will pale in comparison….anyway, press construction.

Legs coming together

From here, we finally had the moment of truth. Will everything fir together? The press was basically 3 parts; a main press cavity and two leg sections. When it was all said and done, I was so stoked that it turned out.

Best toll EVER for getting the legs on

Press finally came together, and looked great.

So then I moved from the house this idea started out to a new house. Located was great because it was with a few blocks of 10 bars….BUT shop wise, conditions were tight. The shop was 13’ x 17’ and had only 2 110V lines. Ek. But I made due, and had to build it up a lot.

Lots of work to go

So now I had to go and make the best of the space I had. So I build up the shop from the ground up.

When the shop was finally done, I was pretty sure even with the less than 300 square feet I had, I could get everything in there and get this all done.

Go tools

After I made the base mold, I had my rocker sections cnc’ed. I wanted to have the ability to easily swap between different rocker sections, so I designed 3 different rockers, between 15 and 35cm that were easily interchangeable.

I then got the cat track cut, top and bottom molds finished, and put the press together.

I use a planer crib to make my cores. I made an adjustable crib that was not perfect, but it works to do almost 110 cores with 9 different core profiles…

Anyway, first ski out of the press was meh. I don’t really know how it happened, but all of a sudden I knew was that suddenly I laying up a ski scared shitless wondering what I was doing. Very very similar to your first time having sex if I remember to my teenage years correctly.

I used WAY too much epoxy.

Cat approve

Next to the FFFs

Next ski came out better.

After getting 2 skis under my belt, I pressed the first pair I would get to ski on.

Skied them up a crystal. Several other people got to use them and everyone seemed to like them.

Git ir done

Buddy david took them out too

Anyway, kept on working and got a few more pairs out. Here is the girlfriend showing off Wren’s wrenegades.

Then things picked up a lot. I stated off expecting to make 7 pairs of skis at first. Well at the end we had produced 52 pairs.

VDS

Cutting jig

Tipspacers

Base material

Fiberglass broken up by size

Some cores

Rest of cores

From here on I could show a ridiculous amount of photos, but I will just throw a handful up.

At the end I had a lot of help from friends just helping me get the skis done. First and foremost, Sam Caylor. His is the man and he cut and finished a ton of skis.

Also David, Billy, Rowen, Will, and Josh all showed up to help get the skis done.

Will with his skis

One of the things that was the hardest part for me was hand cutting the edge notch of the ski. Sometimes I did a good job, other times not as well.

Before

After

Zoe’s custom pair vs. a pair of caylors

Where I lived there was 10+ ally cats. They are great company

Marshal’s Great Scotts getting layed up

Wood veneer

Anyway, that is obviously a lot of photos.

When all was said and done I had made 52 different skis.

Anyway, here is the info about the skis.

191cm Great Scott

145/125/130 corresponding to running length

Running Length = 122cm

Tip rocker = 25cm x 2 or 2.5cm

Tail rocker = 15cm x 1.5cm

Turn Radius = 29.8m

Tapered Tip and Tail

Mount = -8cm

191 Caylor

147/121/144

Running Length = 92cm (go skiboards!)

Tip Rocker = 35cm x 2.5cm

Tail Rocker = 35cm x 2.5cm

Turn Radius = 26.8m

Mount = -3cm

191cm Wrenegade

141/113/128

Running Length = 162cm

Tip Rocker = 15cm x 1.5cm (rec)

Tail Rocker = N/A

Turn Radius = 30.5m

Mount = -9cm

186 Billy Goat

140/115/120 corresponding to running length

Running Length = 117cm

Tip Rocker = 25cm x 2cm

Tail Rocker = 15cm x 1.5cm

Turn Radius = 22.8m

Mount = -7.5cm

186cm Jeronimo

145/115/142

Running Length = 157cm

Tip Rocker = 25cm x 2cm

Tail Rocker = 15cm x 1.5cm

Turn Radius = 21.6m

Mount = -3cm

186cm JBS

132/104/120

Running Length = 157cm

Tip Rocker = 15cm x 1.5cm

Tail Rocker = NA

Turn Radius = 28m

Mount = -7.5cm

179 Custom (unnamed) – Right now full custom

135/110/115 corresponding to running length (15cm tip taper, normal tail)

Running Length = 137cm

Tip Rocker = 15cm x 1.5cm (rec)

Tail Rocker = NA

Turn Radius = 30.5m

Mount = -6cm

179 Blue Steele

111/85/111

Running Length = 150cm

Tip Rocker = NA or 15cm x 1.5cm

Tail Rocker = NA or 15cm x 1.5cm

Turn Radius = 21.6m

Mount = Center

Here is a quiver pic of my skis and the breakdown.

191cm ON3P Great Scott w/ s916. -8cm from center. 145/125/130

191cm ON3P Caylor w/ s916. -3cm from center. 147/121/144

191cm ON3P Wrenegade w/ s916. -9cm from center. 141/113/128

191cm ON3P Wrenegade w/ P12 Demo. -9cm from center. 141/113/128

186cm ON3P Jeronimo w/ s916. -3cm from center. 145/115/142

186cm ON3P Jeronimo w/ P12 Demo. -3cm from center. 145/115/142

186cm ON3P JBS w/ 997 Demo. -7.5cm from center. 132/104/120

179cm ON3P Blue Steele w/ FKS120. Dead Center. 111/85/111

163cm ON3P Customs for the girlfriend. 120/90/110

Rocker shot

As you go along skis: tip rocker: tail rocker

Great Scott: 25cm x 2cm: 15cm x 1.5cm

Caylor: 35cm x 2.5cm: 35cm x 2.5cm

Wrenegade: 15cm x 1.5cm: flat

Wrenegade: 15cm x 1.5cm: flat

Jeronimo: 25cm x 2cm: 25cm x 2cm

Jeronimo: 25cm x 2cm: 25cm x 2cm

JBS: 25cm x 2cm: 15cm x 1.5cm

Blue Steele: flat: flat

Girlfriends skis: 15cm x 1.5cm: flat

and gotta have one of the cats somewhere in the photos

And a few pics of the skis getting tested in Montana over the summer. Skier is David Steele.

Skis are bamboo core, currently PBT topsheet, 4001 race base, 2.2mm/1.3mm edges, VDS, 22oz glass, carbon fiber, fiberglass binding mat.

Production skis if they ever happen would change over to screen printed topsheets as well as bases, UHMW sidewalls (currently bamboo), but otherwise should be pretty similar.

So yeah, I figured I would just get a post out there. If any of the other kids who got skis want to post something up, by all means do. This project has been a huge part of my life and I would love to make it into a full blown ski company.

Ideally I would like to do something where you were given at least a choice in topsheet and flex, and possible rocker, but we shall see.

Right now trying to get funding to get a real shop (hopefully moving from about 300 square feet to 2000-3000 square feet), materials at an affordable cost (right now my cost was huge), and better tools.

Currently in Portland, so if you are skiing around Hood or Crystal/Baker, I should have demos I would love people to try. I have a 301mm boot, too, so if anyone has a boot sole close to mine you are welcomed to try my skis as well.

Questions, comments, etc are definitely welcomes. Even let me know what skis you want made. I definitely have some ideas, but the more input the better.

We should have a website up soon as soon as I can afford it. www.on3pskis.com will be the address. So yeah, that is it mostly. I hope those who got the skis like them And to those hoping to get the skis, hopefully I can make some stuff that you think kicks ass.