You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making my own binding

- Thread starter Keven

- Start date

ASSholebomber22

Active member

Icant_kfed

Active member

Somebody had better put this link in your obituary

SlitherySnake

Active member

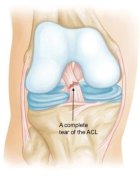

i prefer to just screw my boots directly into my skis and then just take the entire setup on and off

very acl friendly

very acl friendly

a_pla5tic_bag

Active member

14517220:SlitherySnake said:i prefer to just screw my boots directly into my skis and then just take the entire setup on and off

very acl friendly

100% energy transfer, no pesky elasticity in the bindings to ruin your skiing.

SlitherySnake

Active member

14517225:a_pla5tic_bag said:100% energy transfer, no pesky elasticity in the bindings to ruin your skiing.

exactly. gives a really connected feeling that no other binding on the market can offer

PimpChimpin

Active member

Get pivot. Look at pivot. Design pivot. Print pivot.

Skibumsmith

Active member

14517253:tdollo said:Might as well print out some Markers, that’s how they make them in the factory

This is actually how Fritschi makes their bindings.

Skibumsmith

Active member

topic:Keven said:I am trying to 3d print my own binding prototype for a school project. Anybody know where to start?

I'm guessing this is for a high school elective class and the point is to learn some CAD basics and how to use a 3D printer? I like the enthusiasm but this project idea might be a little overzealous. Maybe just find some old bindings from a thrift store and see if you can take them apart and model the pieces in CAD. Look for something with the simplest geometry.

MaimHelp

Active member

Your best bet is to invent your own “bindings” with whatever CAD software you are using by measuring your ski boots with calipers and getting the dimensions and then modeling the bindings so they would have a bit of wiggle room.

these bindings would purely be cosmetic but would be fun to design

these bindings would purely be cosmetic but would be fun to design

alpineplease

Active member

Wrong forum. this has been done plenty. My neighbor 3d prints his own bindings.

“I trust look”

https://www.backcountrytalk.com/forum/gear/bindings/3761-

“I trust look”

https://www.backcountrytalk.com/forum/gear/bindings/3761-

hi_vis360

Active member

14517137:ASSholebomber22 said:

Metabo tools look so fucking sick

skierman

Active member

14517137:ASSholebomber22 said:

LOL at putting trimming on top of trimming. fucking gaper.

hi_vis360

Active member

14517406:skierman said:LOL at putting trimming on top of trimming. fucking gaper.

We did this necessary repair, rent is now $100 more thank you

ASSholebomber22

Active member

14517406:skierman said:LOL at putting trimming on top of trimming. fucking gaper.

I'll let the nice man in the stock photo know, thanks!

SofaKingSick

Active member

top 3 things i wouldn't make at home:

ski bindings

guns

drugs

ski bindings

guns

drugs

ASSholebomber22

Active member

14517419:SofaKingSick said:top 3 things i wouldn't make at home:

ski bindings

guns

drugs

Upvoted for ski bindings

Downvoted for guns and drugs

SofaKingSick

Active member

14517420:ASSholebomber22 said:Upvoted for ski bindings

Downvoted for guns and drugs

look i absolutely wanna see everyone's homemade bindings, drugs, and especially guns (can you rename the thread, OP?), but personally i don't want any of my body parts, brain included, to explode so i'm leaving these 3 to the pros

Paul.

Active member

14517406:skierman said:LOL at putting trimming on top of trimming. fucking gaper.

Looks like new floors and old trim. A little quarter round to cover any gaps makes more sense than replacing all the old trim

skierman

Active member

14517509:Paul. said:Looks like new floors and old trim. A little quarter round to cover any gaps makes more sense than replacing all the old trim

If you're a lazy piece of shit that prefers shitty-looking floors, sure.

rojo.grande

Active member

put your all of your pivots in a will to me before you go any further

SWRTOFFICIAL

Active member

Vish-shoe

Active member

14517512:skierman said:If you're a lazy piece of shit that prefers shitty-looking floors, sure.

This thread really went from discussion of 3d printed bindings to talking about flooring in less than a page

Thegenericskier

Active member

Research some materials like PEEK or Polycarbonate filament and see if you can 3D print those materials because most common materials like PLA, PETG or ABS would likely be nuked if they were actually tested. Also work on how to design assemblies and evaluate their critical tolerances and how to 3D print the parts so the assembly fits as desired.

Schoess

Active member

14517512:skierman said:If you're a lazy piece of shit that prefers shitty-looking floors, sure.

Never heard of quarter round huh? Well maybe if we can get together sometime this week, we could go over how useful quarter round is when you put in a floating floor

dizzydizzy

Member

14517837:Schoess said:Never heard of quarter round huh? Well maybe if we can get together sometime this week, we could go over how useful quarter round is when you put in a floating floor

It also makes sense in certain cases when you have nice but extremely old floors and you install new trim, since the original flooring does not terminate cleanly at the existing wall line. I just did this in my old ass house. Looks quite nice actually, but the quarter round should match the trim, not the floor IMO

GnomeMcGnome

New member

I dont know any CAD files of bindings. But, i think this is a sweet project (dont ride them lol) and I would love to help u prototype if you want!

GrapeHunter

Active member

u dumb idiots the kid said he wanted to make a prototype binding as a school project he didnt say he was going to mount and ride them man u are all so dumb

SofaKingSick

Active member

14518358:GrapeHunter said:u dumb idiots the kid said he wanted to make a prototype binding as a school project he didnt say he was going to mount and ride them man u are all so dumb

OP edited his post, before it said he plans to use the homemade bindings at the Kitzbuhel DH race this year

GrapeHunter

Active member

14518361:SofaKingSick said:OP edited his post, before it said he plans to use the homemade bindings at the Kitzbuhel DH race this year

damn i supported this fraud from the beginning

elm.

Active member

14517817:Thegenericskier said:Research some materials like PEEK or Polycarbonate filament and see if you can 3D print those materials because most common materials like PLA, PETG or ABS would likely be nuked if they were actually tested. Also work on how to design assemblies and evaluate their critical tolerances and how to 3D print the parts so the assembly fits as desired.

PEEK is really expensive and mainly used for high temperature applications. Do a fiberglass or carbon filled ABS.

Geometry is just as important as material choice, too