FullSend_Ski_Co.

Member

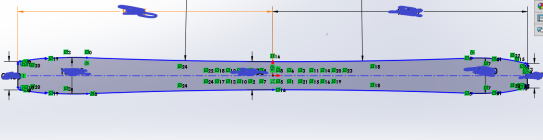

I'm currently building custom skis in South Dakota. Decided to finally post something on newschoolers. Got 4 shapes dialed in along with two different core profiles. Buyers choice of solid base sheet color along with top sheets. My skiing ability is mediocre. My marketing is crap. Product photography is garbage. I here the skis are pretty decent. 40 built and counting.

Shapes are:

133mm-93mm-128mm 14m sidecut

128mm-97mm-124mm 18m sidecut

138mm-107mm-134mm 18m sidecut

145mm-115mm-141mm 18m sidecut

All 184cm long.

https://www.fullsendskico.com/

Shapes are:

133mm-93mm-128mm 14m sidecut

128mm-97mm-124mm 18m sidecut

138mm-107mm-134mm 18m sidecut

145mm-115mm-141mm 18m sidecut

All 184cm long.

https://www.fullsendskico.com/