fouldsys

Active member

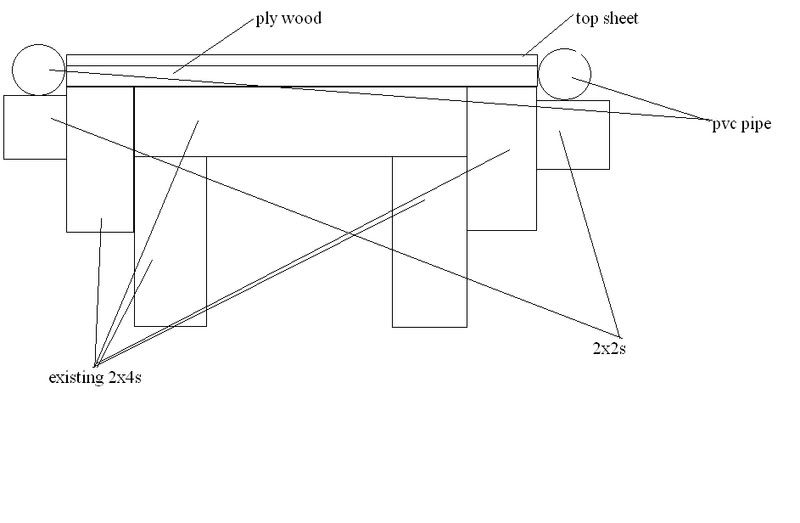

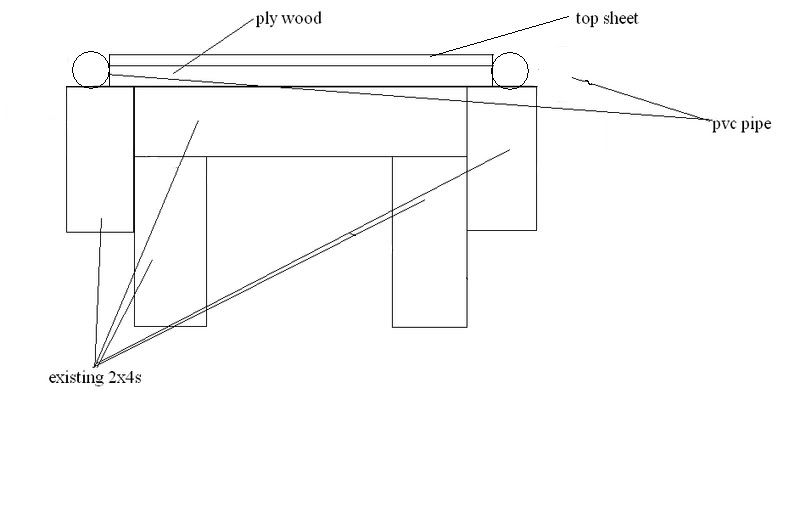

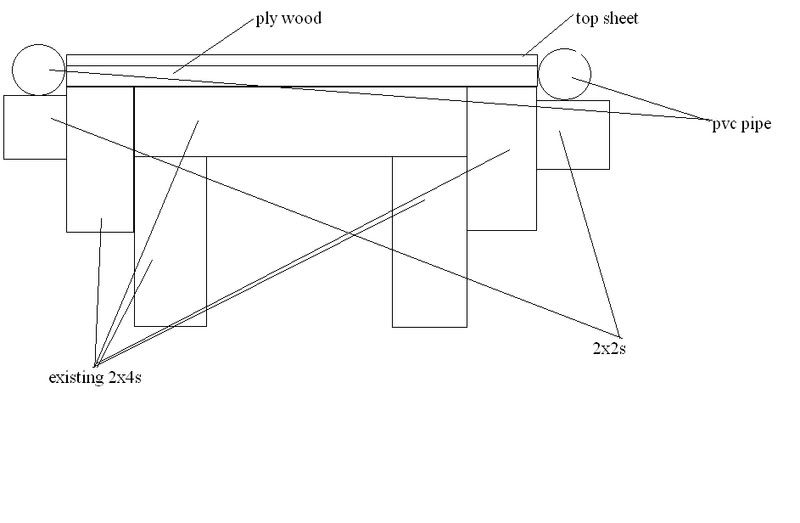

my box has vertical supports(2x4s broad side up) every 2'4" and im going to put 1/2" ply wood over that. what do you suggest the thickness of the top sheet material should be? im getting either hdpe or uhmw. is 1/4" sufficient?

and i was planing on puting some pvc coping on the side. how high should the coping be in relation to the top sheet and how can i attach it to the side of my box? i thought of screwing the pvc into some 2x2s or something and then screwing the 2x2 to the box frame. would that work? heres a pic of what im thinking.

and i was planing on puting some pvc coping on the side. how high should the coping be in relation to the top sheet and how can i attach it to the side of my box? i thought of screwing the pvc into some 2x2s or something and then screwing the 2x2 to the box frame. would that work? heres a pic of what im thinking.