no_steeze

Active member

well today i made some progress, first off i'm just gonna say it is not as easy as it looks in aoe's video haha, it takes a lot of trial and error and jesters are especially easy bindings to do this with

i got some plexi sheets and marked the holes on them, then i clamped the toepiece on the plexi and drilled the first hole. my plan was to screw in each binding screw as i drilled so once i had 2 screws in i would no longer need to clamp it down and the holes would be very accurate. screwed the first screw in and it felt tight but i went slow, next screw put a massive crack through the plexi

i was using a 4,3 bit, it was too small, i'm gonna try a 4,7 next timei was able to salvage the plexi but now i don't have any room for error

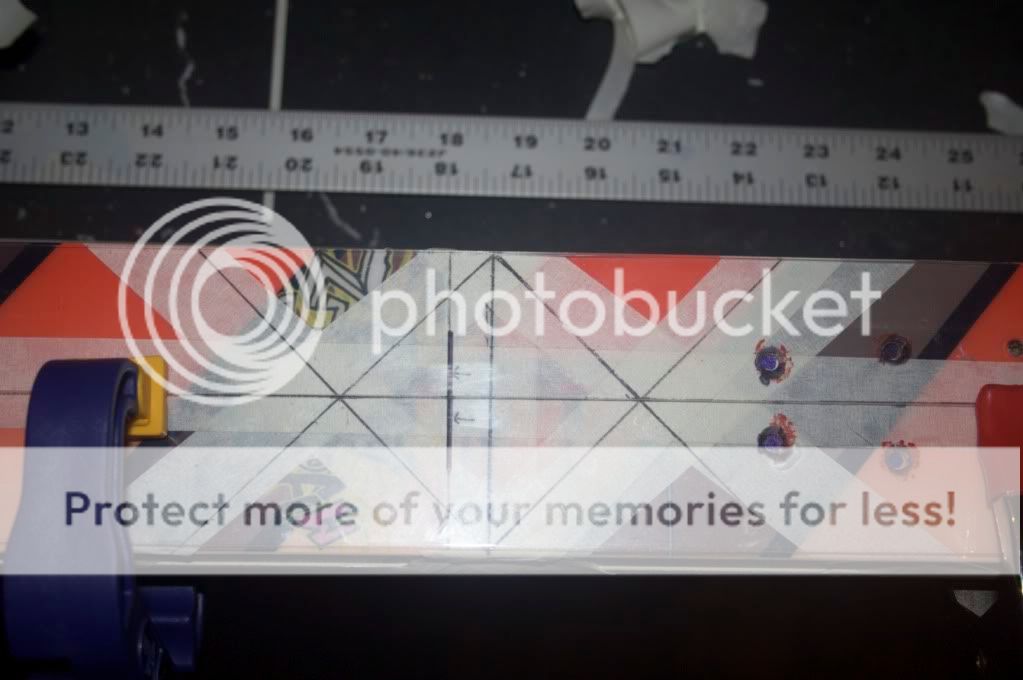

so on the new plexi i have the holes marked and the midsole line for the jig, my dilemma now is that the fks heelpiece won't clamp to the the jig without shooting out and sliding everywhere so i need a way to drill those holes without just winging it because pen marks aren't accurate enough. i'm stumped

i got some plexi sheets and marked the holes on them, then i clamped the toepiece on the plexi and drilled the first hole. my plan was to screw in each binding screw as i drilled so once i had 2 screws in i would no longer need to clamp it down and the holes would be very accurate. screwed the first screw in and it felt tight but i went slow, next screw put a massive crack through the plexi

i was using a 4,3 bit, it was too small, i'm gonna try a 4,7 next timei was able to salvage the plexi but now i don't have any room for error

so on the new plexi i have the holes marked and the midsole line for the jig, my dilemma now is that the fks heelpiece won't clamp to the the jig without shooting out and sliding everywhere so i need a way to drill those holes without just winging it because pen marks aren't accurate enough. i'm stumped